Medium-Tack Film for Smooth & Sandblasted Aluminum

Client Challenge

1. Smooth powder-coated surfaces scratched during stacking, causing gloss differences

2. Sandblasted anodized profiles had compression marks & uneven texture from packaging

Our Solution

1. Medium-tack film for smooth & lightly textured surfaces, no gloss shift or distortion

2. Prevents imprinting on sandblasted finishes while providing strong mechanical protection

3. Guidance on roll pressure & storage to maintain long-term film stability

Results

1. Surface consistency improved across both finishes

2. No edge pressure marks or gloss complaints

3. Packaging workflow faster & more reliable

Client Feedback

“We used to worry about sandblasted finishes getting flattened or shiny spots appearing on coated parts. Since using Alufilm, those issues have disappeared — it protects both types of surface perfectly.”

Medium-Tack Film for Aluminum & Glass

Client Challenge

1.Rough powder-coated aluminum scratched easily, collected dust

2.Glass showed glue marks & paint overspray

Our Solution

1.Dual-use medium-tack film for rough aluminum & glass

2.Strong but safe adhesion, easy to apply & remove

Results

1.70% fewer complaints from installers

2.Clean surfaces, no scratches or glue stains

3.Improved workflow efficiency

Client Feedback

“After switching to Alufilm, we no longer worry about scratches or glue stains.”

Protective Film for Anodized Aluminum

Client Challenge

1. Anodized surfaces scratched easily during stacking & transport

2. Black and copper finishes showed visible defects, leading to complaints

Our Solution

1. Low-to-medium tack film designed for anodized finishes

2. Stable adhesion, no residue, strong resistance to scuffing

3. Guidance on lamination pressure & roll application

Results

1. Surfaces stayed pristine through handling & export

2. Customer complaints dropped significantly

3. Reduced re-polishing & inspection time

Client Feedback

“Before using Alufilm, our black anodized profiles were constantly scratched. Now the finish stays intact—even after export.”

Medium-Tack Film for Smooth Aluminum

Client Challenge

1. Smooth powder-coated & anodized surfaces scratched easily during handling

2. Foam sheets and masking tape left residue or failed to prevent micro-scratches

Our Solution

1. Medium-tack film with balanced adhesion for both finishes

2. Clear coverage, no glue transfer even after long storage

3. Application guidance to ensure bubble-free lamination

Results

1. Surface defects eliminated during production & storage

2. One film used across finishes, boosting efficiency

3. Reduced waste & improved delivery appearance

Client Feedback

“After switching to Alufilm, the difference in surface quality was clear. No more scratches, no more glue stains — and it works on both coated and anodized parts.”

Low-Tack Film for Smooth & Sandblasted Aluminum

Client Challenge

1. Smooth coated surfaces showed fingerprints and smudges

2. Sandblasted anodized aluminum absorbed dust and had pressure marks from packaging

Our Solution

1. Low-tack film for delicate anodized & coated surfaces

2. Clean removal, stable coverage without compressing sandblasted texture

3. Guidance on clean application to reduce particulate entrapment

Results

1. Surface presentation improved at delivery

2. No residue or pressure marks, even on textured finishes

3. Lower rework rate with consistent surface quality

Client Feedback

“Our anodized profiles used to look dull by the time they reached the customer. Since using Alufilm, they look just like they did when they left the line — clean, consistent, and professional.”

Low-Tack Film for Glass Surfaces

Client Challenge

1. Glass suffered scratches, cement splatter & paint overspray during installation

2. Masking tape left residue and failed to cover entire surfaces

Our Solution

1. Specialized low-tack film for direct glass application

2. Easy removal, no residue, strong protection against debris & chemicals

3. Optimized film size & storage to prevent edge curling and dust entrapment

Results

1. Cleaning & polishing time drastically reduced

2. Surface quality consistent even after site exposure

3. Fewer rejected units due to surface damage

Client Feedback

“We used to spend hours cleaning the glass before handover. With Alufilm, we just peel and it’s perfect. It’s saved us time, labor, and customer complaints.”

Medium-High Tack Film for Anodized Profiles

Client Challenge

1. Anodized profiles suffered friction marks, scuffs & dents during transit

2. On-site handling caused scratches & water stains, reducing visual quality

Our Solution

1. Medium-high tack film engineered for anodized architectural systems

2. Strong adhesion, no residue, reliable protection for long-distance shipping

3. Technical guidance on lamination pressure & storage conditions

Results

1. Significant reduction in transport-related surface damage

2. Film performed well in hot, humid storage environments

3. Higher satisfaction from contractors & end users

Client Feedback

“Shipping architectural profiles across the country used to be stressful. With Alufilm, we finally have peace of mind — the finish looks flawless when it arrives.”

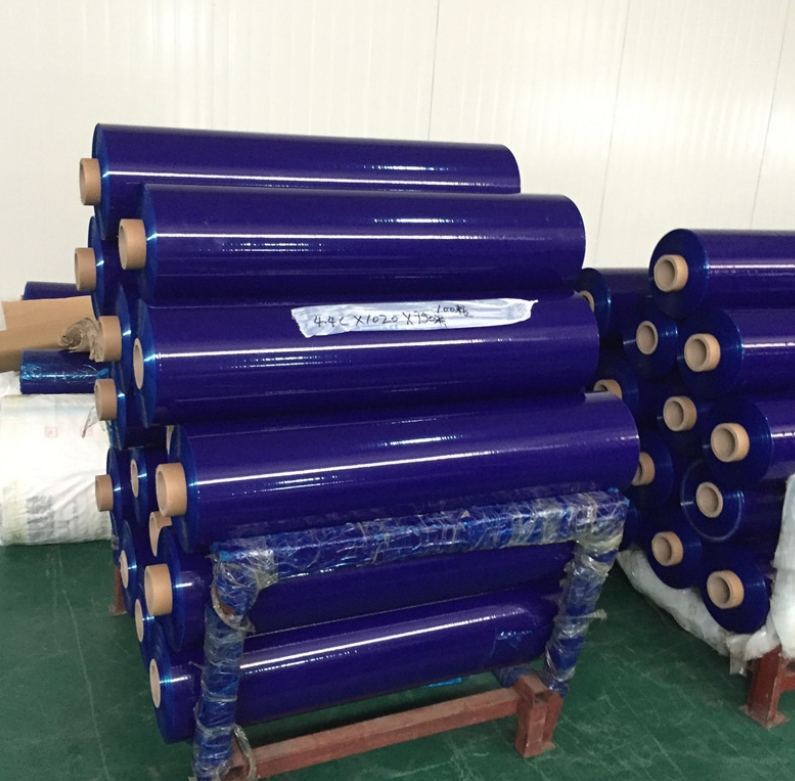

EPE Foam for Protective Packaging

Client Challenge

1. Aluminum profiles & delicate components suffered dents, scratches & impact damage during transport

2. End clients frequently received damaged corners or abrasions

Our Solution

1. High-density EPE foam in rolls, sheets & custom cuts for aluminum packaging

2. Lightweight, shock-absorbing protection for corners, edges & bundled profiles

3. Integration guidance for packaging workflow with minimal labor increase

Results

1. Shipping damage rate dropped significantly, especially for exports

2. Reduced customer complaints & returns

3. Enhanced product presentation at unpacking

Client Feedback

“Our aluminum products used to suffer from scratches or dents when arriving at project sites. Since we started using Alufilm’s EPE foam, our delivery condition has improved dramatically — it’s made a real difference.”

Medium-Tack Film for Matte Powder-Coated Aluminum

Client Challenge

1. Matte powder-coated finishes suffered abrasions & chalky marks from stacking and handling

2. Inconsistent packaging caused edge scuffing & friction lines, affecting customer satisfaction

Our Solution

1. Medium-tack film for delicate matte powder-coated surfaces

2. Optimized adhesion for close contact without damaging the finish

3. Operator training on unwind tension & lamination direction to reduce errors

Results

1. Eliminated surface markings from stacking & contact

2. Consistent appearance across production batches

3. Improved brand image & increased repeat orders

Client Feedback

“Our matte profiles finally stay clean and uniform during storage and shipping. Alufilm helped us solve a long-standing issue and made our packaging much more professional.”

Medium-Tack Film for Matte Powder-Coated Aluminum

Client Challenge

1. Matte finishes marred by fingerprints, dust & rubbing during internal transfer

2. Long-haul shipping caused surface dullness & uneven appearance

Our Solution

1. Medium-tack film protecting matte surfaces from physical & environmental wear

2. Uniform adhesion, prevents lifting & gloss imprinting, allows breathability

3. Guidelines for in-line application post-curing to optimize coverage

Results

1. Surface integrity maintained through storage & shipment

2. Complaints about patchy or dusty finishes decreased

3. Consistent product quality from factory to project site

Client Feedback

“Before using Alufilm, we had to re-clean many profiles after coating. Now, with the film applied straight after painting, we save time and get better feedback from customers.”

Find the Right

Protection Film Custom Solutions

- Experts in LDPE protective films for industrial applications

- Over 20 years of manufacturing excellence

- Trusted by China's top 20 aluminum extrusion companies